In October 2018 we attended the Gore-Tex Brand Snowsports Experience. This is part 1 of our report on that event: a long read on Waterproofness, Gore-Tex Infinium, PFC-EC Free, the winds in Greenland and more.

If anything, in the outdoor world, Gore-Tex has become a household name. Outdoor customers will sometimes be more likely to look and ask for “a Gore-Tex jacket” than a jacket of say Haglöfs, Berghaus, the North Face or any other specific  brand using their laminates. How is it that an “ingredient brand” as Gore-tex describes itself, is in some cases better known than the clients they service?

During the Gore-Tex SnowSports Experience I got the opportunity to ask this, and many other questions to the representative of the brand during the four seminar sessions and out on the slopes of Kaprun.

brand using their laminates. How is it that an “ingredient brand” as Gore-tex describes itself, is in some cases better known than the clients they service?

During the Gore-Tex SnowSports Experience I got the opportunity to ask this, and many other questions to the representative of the brand during the four seminar sessions and out on the slopes of Kaprun.

brand using their laminates. How is it that an “ingredient brand” as Gore-tex describes itself, is in some cases better known than the clients they service?

During the Gore-Tex SnowSports Experience I got the opportunity to ask this, and many other questions to the representative of the brand during the four seminar sessions and out on the slopes of Kaprun.

brand using their laminates. How is it that an “ingredient brand” as Gore-tex describes itself, is in some cases better known than the clients they service?

During the Gore-Tex SnowSports Experience I got the opportunity to ask this, and many other questions to the representative of the brand during the four seminar sessions and out on the slopes of Kaprun. Ingredient brand

I thought it was an interesting choice of words, calling yourself an ingredient brand. But it is on-point, Gore-Tex not (as of yet) producing finished products to market under its own name, but rather providing many outdoor brands with the materials needed to produce highly breathable and highly waterproof materials. But how does that work? What Gore-Tex does is deliver complete laminates to their clients. What that means is that from receiving the textile in whatever color the client wants, they will apply the Gore-Tex waterproof membrane, a third layer if need be, laminate these layers and apply a DWR (Durable Water Repellent) coating to that. After that, it is up to the client to manufacture the end product.

There are various “intensity” if you will, to the products. From Gore-Tex Pro garments, which are heavy, strong, robust, to lighter and more stretch Gore-Tex Active or even Shake Dry Garments where the outer layer is actually the Gore-Tex membrane itself. Within this group of products, Gore-Tex has the “Guaranteed to Keep You Dry.” promise.

waterproof membrane, a third layer if need be, laminate these layers and apply a DWR (Durable Water Repellent) coating to that. After that, it is up to the client to manufacture the end product.

There are various “intensity” if you will, to the products. From Gore-Tex Pro garments, which are heavy, strong, robust, to lighter and more stretch Gore-Tex Active or even Shake Dry Garments where the outer layer is actually the Gore-Tex membrane itself. Within this group of products, Gore-Tex has the “Guaranteed to Keep You Dry.” promise.Waterproofness & Breathability

And that is why Gore-Tex has become almost synonymous to waterproofness. But there is actually a lot more going on. Making something waterproof is not actually that difficult. Making something that is waterproof and breathable, is. This breathability ensures that you do not get wet from the inside. Keeping dry from within and without is the golden combination, with at it’s core the Gore-Tex membrane. The microporous membrane with pores that are too small to let rain/water come through, but large enough to allow perspiration moisture out. This results in what we call breathability: the garments breath more easily, and depending on the layers you wear underneath the waterproof jacket, your body will be able to lose more of its excess warmth as you become active.

There is a limit though, to that breathability: it is not as if you will not sweat even with the best layering and highest tech. It is just physiology; the body needs to get rid of that excess warmth. So the best you can ask of your layers is to have them transport that excess warmth away from your body as quickly as possible while staying as dry as possible.

The microporous membrane with pores that are too small to let rain/water come through, but large enough to allow perspiration moisture out. This results in what we call breathability: the garments breath more easily, and depending on the layers you wear underneath the waterproof jacket, your body will be able to lose more of its excess warmth as you become active.

There is a limit though, to that breathability: it is not as if you will not sweat even with the best layering and highest tech. It is just physiology; the body needs to get rid of that excess warmth. So the best you can ask of your layers is to have them transport that excess warmth away from your body as quickly as possible while staying as dry as possible.Fabric and DWR-coating

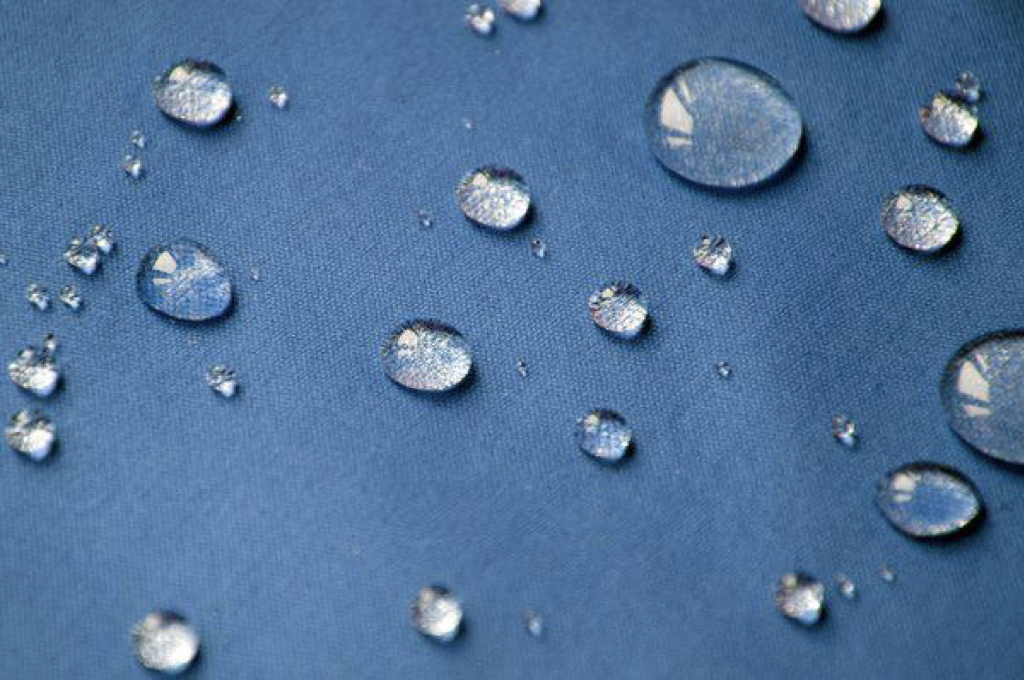

The outer fabric of the garment and especially the DWR coating used are also of great importance for waterproofness and breathbaility. The way the fabric is weaved will determine how much rain/water can come through, but even before that, the DWR coating on it is the first line of defense. The object of this coating is to ensure that the outer fabric is not saturated with water, (also called “wetting-out”) because that will lessen the breathability of this outer layer (the last hurdle for transpiration moisture to definitely escape from your body). What you are looking for in a DWR is that it causes rain to form droplets, and roll off the fabric as quickly as possible. This is what is called a hydrophobic effect.

There are down-sides to these DWR’s and one of the most important ones is that most coatings used are PFC (Perfluorinated compound) based and contain fluoropolymer. As the DWR coating deteriorates (which it will do with wear), the fluor can find it’s way into the natural environment and is quite harmful to it. PFC’s are everywhere and used in a lot of different applications, and there are hundreds of variations.

Talking to Gore-Tex about this issue of PFC’s which is broadly discussed in the outdoor industry, I notice they are acutely aware of this issue. According to Christian Mayer, Product specialist GORE-TEX garments, unfortunately, at this time there is no PFC-free alternative that works as well as the coatings they use. And when you are in uncompromising circumstances, where good waterproofness and breathability can mean the difference between life and death, Gore-Tex does not want to compromise on the performance of the DWR used. So in their Pro Garments, they still use these non-environmental coatings.

The outer fabric of the garment and especially the DWR coating used are also of great importance for waterproofness and breathbaility. The way the fabric is weaved will determine how much rain/water can come through, but even before that, the DWR coating on it is the first line of defense. The object of this coating is to ensure that the outer fabric is not saturated with water, (also called “wetting-out”) because that will lessen the breathability of this outer layer (the last hurdle for transpiration moisture to definitely escape from your body). What you are looking for in a DWR is that it causes rain to form droplets, and roll off the fabric as quickly as possible. This is what is called a hydrophobic effect.

There are down-sides to these DWR’s and one of the most important ones is that most coatings used are PFC (Perfluorinated compound) based and contain fluoropolymer. As the DWR coating deteriorates (which it will do with wear), the fluor can find it’s way into the natural environment and is quite harmful to it. PFC’s are everywhere and used in a lot of different applications, and there are hundreds of variations.

Talking to Gore-Tex about this issue of PFC’s which is broadly discussed in the outdoor industry, I notice they are acutely aware of this issue. According to Christian Mayer, Product specialist GORE-TEX garments, unfortunately, at this time there is no PFC-free alternative that works as well as the coatings they use. And when you are in uncompromising circumstances, where good waterproofness and breathability can mean the difference between life and death, Gore-Tex does not want to compromise on the performance of the DWR used. So in their Pro Garments, they still use these non-environmental coatings.

In other less exacting lines, however, there is an ongoing search for coatings with less of a negative impact on the environment. In conjunction with Greenpeace, Gore-Tex have established which PFC’s are of “Environmental Concern” and which are not. The company has introduced the first PFC-EC Free garments this year and has set various goals on eliminating PFC-EC from its membrane for 85% in 2020 and to only use PFC-EC free coatings in all their materials in 2023. Sustainability steps have also been taken in new dyeing techniques, saving up to 60% water on fiber dye, and using more recycled textiles. These “new” products are already on the market.

One of the often overlooked elements in the discussion on materials and fabrication processes and direct environmental impact is the life-span of a product. In my opinion, it might perhaps be one of the more important elements of sustainability. With Gore-Tex products, the lifespan is an average of 5 years. Elongating that lifespan is crucial to the company.

It is an important and fascinating tension that each company in the outdoor industry (and beyond) should feel: between high-performance on the relatively short run, and looking for those alternatives that offer more sustainable and durable solutions. The talks I had, in the seminars and over dinner with the people from Gore-Tex where really interesting and it is encouraging to notice that it is a priority to the company.

Given the fact that Gore-Tex has the power to strongly motivate and sometimes even dictate certain terms of production to their own clients, it is in a unique position to play a really big role in making the outdoor sector more sustainable. As Spiderman would say: “With great power comes great responsibility!”

In other less exacting lines, however, there is an ongoing search for coatings with less of a negative impact on the environment. In conjunction with Greenpeace, Gore-Tex have established which PFC’s are of “Environmental Concern” and which are not. The company has introduced the first PFC-EC Free garments this year and has set various goals on eliminating PFC-EC from its membrane for 85% in 2020 and to only use PFC-EC free coatings in all their materials in 2023. Sustainability steps have also been taken in new dyeing techniques, saving up to 60% water on fiber dye, and using more recycled textiles. These “new” products are already on the market.

One of the often overlooked elements in the discussion on materials and fabrication processes and direct environmental impact is the life-span of a product. In my opinion, it might perhaps be one of the more important elements of sustainability. With Gore-Tex products, the lifespan is an average of 5 years. Elongating that lifespan is crucial to the company.

It is an important and fascinating tension that each company in the outdoor industry (and beyond) should feel: between high-performance on the relatively short run, and looking for those alternatives that offer more sustainable and durable solutions. The talks I had, in the seminars and over dinner with the people from Gore-Tex where really interesting and it is encouraging to notice that it is a priority to the company.

Given the fact that Gore-Tex has the power to strongly motivate and sometimes even dictate certain terms of production to their own clients, it is in a unique position to play a really big role in making the outdoor sector more sustainable. As Spiderman would say: “With great power comes great responsibility!”